What Is A Control Chart . It's a specialized run chart. Control charts are used to routinely monitor quality.

Control Chart: A Key Tool For Ensuring Quality And Minimizing Variation | Lucidchart Blog from www.lucidchart.com

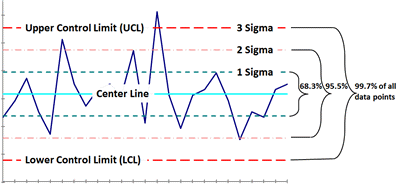

Control charts are commonly used in the production process to determine whether there is a trend in a process that is moving beyond predetermined control limits. The control chart tool is part of the quality control management and it is a graphic display of the data against established control limits to reflect both the maximum and minimum values. If you have information about your business that you want to measure and analyze, such as manufacturing defects, patient wait times or how long customers take to pay, the control chart can map out the data over time.

Control Chart: A Key Tool For Ensuring Quality And Minimizing Variation | Lucidchart Blog

A control chart is used to monitor a process variable over time. If problems appear to arise, the quality control chart can. A control chart—sometimes called a shewhart chart, a statistical process control chart, or an spc chart—is one of several graphical tools typically used in quality control analysis to understand how a process changes over time. Control chart is a modern quality control tool which falls under the broad heading of statistical process control.

Source: www.isixsigma.com

Control charts are commonly used in the production process to determine whether there is a trend in a process that is moving beyond predetermined control limits. What is a process control chart? It's a specialized run chart. You may hear this chart referred to as a shewhart chart. A control chart is a graphical representation of process variables over time.

Source: www.youtube.com

A control chart is used to monitor a process variable over time. Whilst this chart still plots a single line of data, it also displays an upper line for the upper control limit and a lower line for the lower control limit. If so, action is taken to move the process back within the control limits. There are several types.

Source: en.wikipedia.org

A control chart is a graph which displays all the process data in order sequence. If so, action is taken to move the process back within the control limits. Control chart is a modern quality control tool which falls under the broad heading of statistical process control. The control chart tool is part of the quality control management and it.

Source: blog.kainexus.com

It provides a picture of the process variable over time and represents the way the process communicates with you. If problems appear to arise, the quality control chart can. The second, referred to as A control chart begins with a time series graph. On the number of process characteristics to be monitored, there are two basic types of control charts.

Source: www.itl.nist.gov

What is a control chart? How can you use it to monitor processes?what is the ucl, lcl and center line (cl) of a control chart? It provides a picture of the process variable over time and represents the way the process communicates with you. In statistics, control charts are the tools in control processes to determine whether a manufacturing process.

Source: www.spcforexcel.com

There are several types of charts that we’re almost too familiar of, like flowcharts, pie charts, bar charts, etc., since we have been learning from them for quite a long time.one of such charts is a control chart, which we will be discussing in this post. A control chart is a graphical representation of process variables over time. The control.

Source: techqualitypedia.com

Control charts are used to routinely monitor quality. If you have information about your business that you want to measure and analyze, such as manufacturing defects, patient wait times or how long customers take to pay, the control chart can map out the data over time. It provides a picture of the process variable over time and represents the way.

Source: en.wikipedia.org

A control chart begins with a time series graph. By listening to what your process is telling you. Elements of a control chart. How can you use it to monitor processes?what is the ucl, lcl and center line (cl) of a control chart? Control charts are commonly used in the production process to determine whether there is a trend in.

Source: asq.org

A control chart is a tool that is used to determine the predictability, behavior and stability of the process over time. It's a specialized run chart. A control chart is a graphical representation of process variables over time. A control chart—sometimes called a shewhart chart, a statistical process control chart, or an spc chart—is one of several graphical tools typically.

Source: www.clearpointstrategy.com

Control chart is a modern quality control tool which falls under the broad heading of statistical process control. A control chart is a graphical representation of process variables over time. Whilst this chart still plots a single line of data, it also displays an upper line for the upper control limit and a lower line for the lower control limit..

Source: www.itl.nist.gov

Some additional horizontal lines representing the average measurement and control limits are frequently drawn across a control chart. It provides a picture of the process variable over time and represents the way the process communicates with you. There are several types of charts that we’re almost too familiar of, like flowcharts, pie charts, bar charts, etc., since we have been.

Source: www.qualitymag.com

Elements of a control chart. There are three main elements of a control chart as shown in figure 3. Centre line of a chart represents the process average. Control charts are commonly used in the production process to determine whether there is a trend in a process that is moving beyond predetermined control limits. Control charts a control chart is.

Source: www.qimacros.com

In other words, they provide a great way to monitor any sort of process you have in place so you can learn how to improve your poor performance and continue with your successes. There are several types of charts that we’re almost too familiar of, like flowcharts, pie charts, bar charts, etc., since we have been learning from them for.

Source: www.lucidchart.com

If problems appear to arise, the quality control chart can. It's a specialized run chart. A control chart is used to monitor a process variable over time. The purpose of a control chart is to set upper and lower bounds of acceptable performance given normal variation. Centre line of a chart represents the process average.

Source: www.spcforexcel.com

A control chart is a tool that is used to determine the predictability, behavior and stability of the process over time. Control charts are commonly used in the production process to determine whether there is a trend in a process that is moving beyond predetermined control limits. Whilst this chart still plots a single line of data, it also displays.

Source: www.educba.com

Elements of a control chart. If problems appear to arise, the quality control chart can. The first, referred to as a univariate control chart, is a graphical display (chart) of onequality characteristic. In other words, they provide a great way to monitor any sort of process you have in place so you can learn how to improve your poor performance.

Source: blog.kainexus.com

You may hear this chart referred to as a shewhart chart. The purpose of a control chart is to set upper and lower bounds of acceptable performance given normal variation. The first, referred to as a univariate control chart, is a graphical display (chart) of onequality characteristic. In the same way, engineers must take a special look to points beyond.

Source: acqnotes.com

It consists of a centre line, the upper limit and lower limit. You may hear this chart referred to as a shewhart chart. Control charts are used to routinely monitor quality. Charts convey information through the aid of graphic symbols, images, and diagrams. If so, action is taken to move the process back within the control limits.

Source: www.qimacros.com

A quality control chart is a graphical representation of whether a firm's products or processes are meeting their intended specifications. A control chart is a method for measuring change. The purpose of a control chart is to set upper and lower bounds of acceptable performance given normal variation. Control chart and run chart can be identified as statistical tools used.

Source: www.medcalc.org

What is a control chart? Control charts consist of product or process measurements over time and are a graphical representation of the variation between those measurements (or between subgroups of those measurements). You may hear this chart referred to as a shewhart chart. Whilst this chart still plots a single line of data, it also displays an upper line for.