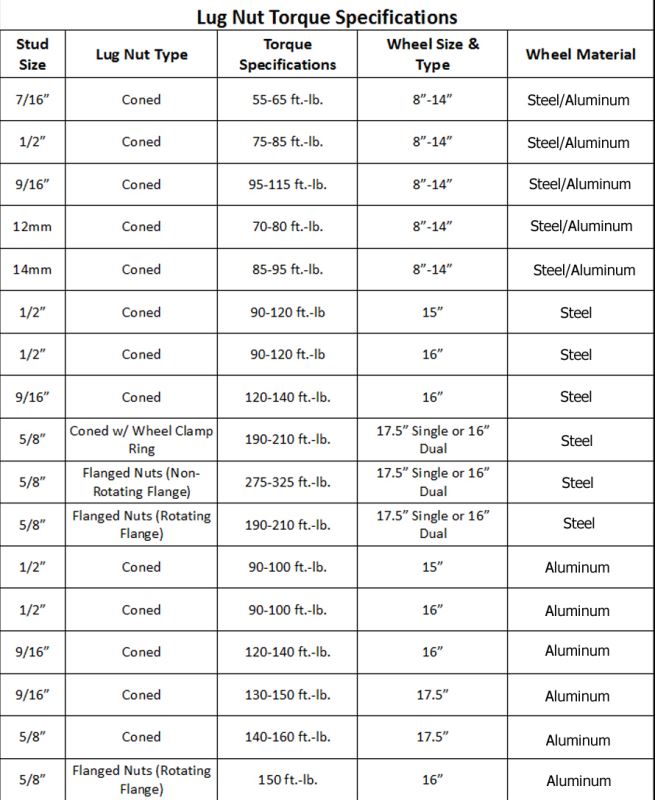

Trailer Wheel Lug Nut Torque Chart Pdf . Lbs.) make/model years torque acura all models except: If you do not have a torque wrench, tighten the lug nuts with a lug wrench as much

What Is The Torque Specification For An 8 Inch Diameter Trailer Wheel | Etrailer.com from www.etrailer.com

(figure i) this will ensure the wheel studs are centered in the wheel holes, and will help the lug nuts maintain proper torque. Wheel nut torque specifications (shown in ft. After wheel lug nuts are.

What Is The Torque Specification For An 8 Inch Diameter Trailer Wheel | Etrailer.com

Use a torque wrench to obtain the proper tightening of the lug nuts (or bolts). Wheel nut torque specifications (shown in ft. Below is my latest wheel lug nut torque chart. If you do not have a torque wrench, tighten the lug nuts with a lug wrench as much

Source: www.etrailer.com

You must follow all safety precautions and instructions. Use appropriately rated jack stands. Loosen wheel lug nuts before raising the trailer to prevent tire from spinning during lug nut removal. For all model years up to2019 torque chart land rover cont’d freelander2002. Wheel lug nuts should be torqued before first road use and after each wheel removal.

Source: www.rib.net

Big tex trailer manufacturing, llc. Attach new wheel to the axle hub as follows: If you do not have a torque wrench, tighten the lug nuts with a lug wrench as much For all model years up to2019 torque chart land rover cont’d freelander2002. Wheel nuts can cause the wheel to separate from the wheel mounting surface during operation.

Source: scampowners.com

• during wheel reinstallation, the lug nut torque must be applied in 3 stages. No lubricant should be used on the threads of either the stud or the nut, but these should be clean and free form rust or. Start all lug nuts by hand. You must follow all safety precautions and instructions. Warning this user’s manual contains safety information.

Source: www.felling.com

Lbs.) wheel lug nuts should. Lug nut torque chart for trailer wheels. You must read this manual before loading or towing your trailer. Wij willen hier een beschrijving geven, maar de site die u nu bekijkt staat dit niet toe. Wheels 22 wheel selection 22 torque requirements 22 tires 23 introduction to troubleshooting 24 troubleshooting 24 troubleshooting chart 25 measuring.

Source: www.jaycoowners.com

Torque wheel lug nuts to the torque values listed in the wheel torque requirement chart. After lug nuts have been loosened, raise the trailer until the tire spins freely. Start all lug nuts by hand. Wheel nut torque specifications (shown in ft. Make sure wheel fasteners match the cone angle of the wheel (usually 60°or 90°) being serviced.

Source: www.forestriverforums.com

You should always consult with the wheel manufacturer to determine the appropriate torque level for you wheels. Loosen wheel lug nuts before raising the trailer to prevent tire from spinning during lug nut removal. Place jack stands under the trailer's. If you would like to download a pdf. Wheels 22 wheel selection 22 torque requirements 22 tires 23 introduction to.

Source: www.pinterest.com

Attach new wheel to the axle hub as follows: Loosen wheel lug nuts before raising the trailer to prevent tire from spinning during lug nut removal. Pdf created with pdffactory trial version www.pdffactory.com Wheels 22 wheel selection 22 torque requirements 22 tires 23 introduction to troubleshooting 24 troubleshooting 24 troubleshooting chart 25 measuring voltage 25 measuring amperage 25 amperage chart.

Source: www.etrailer.com

You must follow all safety precautions and instructions. (figure i) this will ensure the wheel studs are centered in the wheel holes, and will help the lug nuts maintain proper torque. Wij willen hier een beschrijving geven, maar de site die u nu bekijkt staat dit niet toe. Torque is a measure of the amount of tightening applied to a.

Source: recstuff.com

Using the proper torque helps ensure that the wheel assembly is securely installed. Start all lug nuts by hand. Through all vehicle manufacturers or authorized alcoa distributors. If you are planning on installing a wheel on your vehicle, it is important to be aware of the manufacturer recommended torque settings. If you would like to download a pdf.

Source: www.speedwaymotors.com

Using the proper torque helps ensure that the wheel assembly is securely installed. Wheel lug nuts should be torqued before first road use and after each wheel removal. This wheel lug torque chart is collected information from many different resources to get you as much up to date specs as possible. Limited trailer 1999 410841(6 lug). Make sure wheel fasteners.

Source: www.forestriverforums.com

After lug nuts have been loosened, raise the trailer until the tire spins freely. As torque specifications become available, this table will be updated regularly. 23 rows wheel torque requirements sequence (ft. After wheel lug nuts are. Through all vehicle manufacturers or authorized alcoa distributors.

Source: www.mtfca.com

Loosen wheel lug nuts before raising the trailer to prevent tire from spinning during lug nut removal. If you would like to download a pdf. Big tex trailer manufacturing, llc. Wheel nuts can cause the wheel to separate from the wheel mounting surface during operation. For all model years up to2019 torque chart land rover cont’d freelander2002.

Source: www.coastresorts.com

Lbs.) wheel lug nuts should. Lug nuts are prone to loosen after assembly. Wheel nut torques should be set using a calibrated torque wrench and checked, as is normal automotive practice, after the first 50km following removal and refitting. Australian off road in consultation with hub manufacturers and numerous wheel manufacturers have created a guide for wheel nut settings for.

Source: www.popupportal.com

Through all vehicle manufacturers or authorized alcoa distributors. If you do not have a torque wrench, tighten the lug nuts with a lug wrench as much In order to determine the torque rating for the lug nuts on your trailer you will need to know check out the chart i attached that shows all of the torque specs for all.

Source: www.carsontrailer.com

75th anniversary wheel lug nut reference: Warning tighten each lug nut in the order shown to the torque shown in the chart. After lug nuts have been loosened, raise the trailer until the tire spins freely. As torque specifications become available, this table will be updated regularly. Two piece nut or two piece sleeved nut according to din 74361 standards.

Source: scoutingweb.com

Wheel and torque specifications wheel and tire information tires. The table can be filtered and is searchable. Wij willen hier een beschrijving geven, maar de site die u nu bekijkt staat dit niet toe. Wheel nuts can cause the wheel to separate from the wheel mounting surface during operation. Using the proper torque helps ensure that the wheel assembly is.

Source: www.rv.net

Start all lug nuts by hand. Lug nut torque chart for trailer wheels. Loosen wheel lug nuts before raising the trailer to prevent tire from spinning during lug nut removal. If you are planning on installing a wheel on your vehicle, it is important to be aware of the manufacturer recommended torque settings. This wheel lug torque chart is collected.

Source:

Two piece nut or two piece sleeved nut according to din 74361 standards mounting : No lubricant should be used on the threads of either the stud or the nut, but these should be clean and free form rust or. Use a torque wrench to obtain the proper tightening of the lug nuts (or bolts). Lug nut torque chart for.

Source: forum.ih8mud.com

Loosen wheel lug nuts before raising the trailer to prevent tire from spinning during lug nut removal. In order to determine the torque rating for the lug nuts on your trailer you will need to know check out the chart i attached that shows all of the torque specs for all the trailer lugs available based on stud size, wheel.

Source: garage.grumpysperformance.com

75th anniversary wheel lug nut reference: Continue to lift and support trailer per manufacturer’s requirements. If you would like to download a pdf. Wheel nut torques should be set using a calibrated torque wrench and checked, as is normal automotive practice, after the first 50km following removal and refitting. You must follow all safety precautions and instructions.