Rockwell Hardness Chart For Metals . The equation for the rockwell hardness test for metals is below: The hardness level of steel is determined using a universal scale called the “rockwell c test”, commonly called the rockwell hardness scale (hrc).

Understanding Rockwell | Agrussell.com from agrussell.com

The specimen can be either molded or cut from a plastic sheet. The rockwell scale is a hardness scale based on indentation hardness of a material. Astm e 140, standard hardness conversion tables for metals, (for information on where to find, see at the end of this publication) is the best known and authoritative such

Understanding Rockwell | Agrussell.com

The two letters hr, standing for hardness according to rockwell. The ability of steel to retain its original shape is measured on the rockwell c scale, also known as hardness rockwell c (hrc). Hardness is defined as resistance of a material to penetrationof its surface, and the majority of commercial hardness testers force a small penetrator (indenter)into the metal by means of an applied load. Indentation hardness is not a single fundamental property but a combination of properties,.

Source: www.researchgate.net

This table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. The charts cover the following : Hardness 10 kgf 500 gf & over equiv. 5.5.a standard specimen of 0.25 in. Hardness conversion chart & calculator rockwell hardness brinell hardness.

Source: myarmoury.com

The rockwell scale designation, defining the combination of main load (total test force) and type of indenter used in the corresponding rockwell method. The rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods. Hardness conversion chart & calculator rockwell hardness brinell hardness. You should obtain a copy of this standard, read and.

Source: www.mem50212.com

These conversion tables presents data in the rockwell a, b, c, d, e and f hardness range on the relationship. The equation for the rockwell hardness test for metals is below: The rockwell hardness scale is symbolized by hr followed by a letter indicating any of the possible scales. For the errors in using a conversion chart. The rockwell scale.

Source: jjjtrain.com

For the errors in using a conversion chart. To accurately express metal hardness, engineers use a standard process called rockwell testing. Hardness 10 kgf 500 gf & over equiv. The below chart is useful for determining which metals will be impervious to scratching and dinging, as it relates to the rockwell scale and ductility. The two letters hr, standing for.

Source: metallography-matters.buehler.com

The rockwell hardness chart for metals was created by harold f. The rockwell hardness scale is symbolized by hr followed by a letter indicating any of the possible scales. The ability of steel to retain its original shape is measured on the rockwell c scale, also known as hardness rockwell c (hrc). Manufactured products are made of. The charts cover.

Source: www.gordonengland.co.uk

Knife rockwell hardness aka hrc These conversion charts are provided for guidance only as each scales uses different methods of measuring hardness. The right hand column show an approximate equivalent tensile strength. The ability of steel to retain its original shape is measured on the rockwell c scale, also known as hardness rockwell c (hrc). The below chart is useful.

Source: www.jewelry-secrets.com

5.5.a standard specimen of 0.25 in. You should obtain a copy of this standard, read and understand the standard completely before attempting a rockwell test. The right hand column show an approximate equivalent tensile strength. The ability of steel to retain its original shape is measured on the rockwell c scale, also known as hardness rockwell c (hrc). The equation.

Source: tubingchina.com

The hardness level of steel is determined using a universal scale called the “rockwell c test”, commonly called the rockwell hardness scale (hrc). Manufactured products are made of. For example, “hrc 96” for a metal means the hardness of that metal is 96 when measured using rockwell hardness scale c. In general, a knife must have an hrc of at.

Source: agrussell.com

The ability of steel to retain its original shape is measured on the rockwell c scale, also known as hardness rockwell c (hrc). Janka is used exclusively for wood, but it can be very helpful when cnc’ing wood. The rockwell hardness chart for metals was created by harold f. Hardness conversion between different methods and scales cannot be made mathematically.

Source: www.ws-stahl.eu

This table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. The rockwell hardness chart for metals was created by harold f. Rockwell hardness (hrc and hrb) and brinell hardness (hb or bhn) are most commonly used for steel and iron castings. To accurately express metal hardness, engineers use a standard process called rockwell testing..

Source: www.ws-stahl.eu

The rockwell hardness chart for metals was created by harold f. The two letters hr, standing for hardness according to rockwell. A rockwell hardness value consists of three components: (6.35 mm) minimum thickness is used. D=depth from zero load point.

Source: roslerblog.com

Strength is a critical factor in metal uses, for example, some applications require stronger aluminum parts, while some products need high steel hardness or yield strength of steel, this may determine the selection of cnc machining material or product design. The specimen can be either molded or cut from a plastic sheet. The below chart is useful for determining which.

Source: www.offgridweb.com

Rockwell hardness (hrc and hrb) and brinell hardness (hb or bhn) are most commonly used for steel and iron castings. The rockwell scale designation, defining the combination of main load (total test force) and type of indenter used in the corresponding rockwell method. Practical hardness testing made simple 1 1. 5.5.a standard specimen of 0.25 in. Rockwell hardness, superficial hardness,.

Source: www.hardnesstesters.com

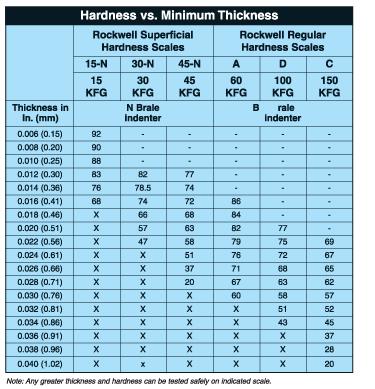

A rockwell hardness value consists of three components: The equation for the rockwell hardness test for metals is below: Practical hardness testing made simple 1 1. Sheet metal as thin as 0.006 inch can be tested on the rockwell N and s = various scale factors that can be found in the chart below.

Source: willrich.com

Below are a few charts that will help you choose the proper set up for your ames rockwell portable hardness tester. Janka is used exclusively for wood, but it can be very helpful when cnc’ing wood. Rockwell hardness (hrc and hrb) and brinell hardness (hb or bhn) are most commonly used for steel and iron castings. Hardness conversion between different.

Source: www.industrialheating.com

Rockwell hardness (hrc and hrb) and brinell hardness (hb or bhn) are most commonly used for steel and iron castings. Hardness is very important for the production of rough metal castings, heat treatment and machining processes. Metal products distributor supplier metals and materials. Hardness is defined as resistance of a material to penetrationof its surface, and the majority of commercial.

Source: www.azahner.com

Metal products distributor supplier metals and materials. Hardness, or hrc, is a metric referring to a steel's resistance to heat, stress, and other forces regularly applied to knives. For example, “hrc 96” for a metal means the hardness of that metal is 96 when measured using rockwell hardness scale c. The higher the number on the rc scale, the harder.

Source: www.pinterest.com

To accurately express metal hardness, engineers use a standard process called rockwell testing. The two letters hr, standing for hardness according to rockwell. Manufactured products are made of. The specimen can be either molded or cut from a plastic sheet. Astm e 140, standard hardness conversion tables for metals, (for information on where to find, see at the end of.

Source: www.thefabricator.com

In the knife blade manufacturing business, hardness ratings follow a predetermined chart which is commonly called the rockwell c scale. For example, “hrc 96” for a metal means the hardness of that metal is 96 when measured using rockwell hardness scale c. The ability of steel to retain its original shape is measured on the rockwell c scale, also known.

Source: www.matweb.com

(6.35 mm) minimum thickness is used. Rockwell hardness is determined using an apparatus called the rockwell hardness tester as shown in fig. You should obtain a copy of this standard, read and understand the standard completely before attempting a rockwell test. Indentation hardness is not a single fundamental property but a combination of properties,. Rockwell hardness, superficial hardness, knoop hardness,.