Concrete Curing Temperature Chart . If using an enclosure, ensure that the structure is both wind and waterproof. The period can be reduced to 3 days if

Role Of Concrete Curing from www.cement.org

Life of any concrete structure primarily depends on the compressive strength of concrete and it is very important for any concrete construction project. For applications outside this range of temperatures and conditions, contact sakrete technical service. Maintaining the proper temperature also plays a vital role in concrete as mentioned, it should not be colder than 5 0 c.

Role Of Concrete Curing

So the objective is to keep our young and impressionable concrete damp and at the right temperature (ideally between 50 and 85 f). Concrete is to achieve its potential strength and durability. The effect of concrete temperature and retardation of setting time is given by pca in the chart below. Curing is maintaining adequate moisture or humidity of 80% and temperature higher than 50°f over 3 to 14 days after the pour.

Source: jaybird-mfg.com

With curing, the period should be as long as practical. Casting temperatures,curing compressive strength, final set,initial slump, temperature effects. Most of the common people does not know the minimum curing period o. (if the temperature is below 72 degrees, additional time for curing will be required.) Digital vs chart recorder one of the requirements of astm c511 is that your.

Source: onsiteco.com

For most concrete structures, the curing period at temperatures above 5º c (40º f) should be a minimum of 7 days or until 70% of the specified compressive or flexural strength is attained. In a perfect world, the temperature of fresh concrete should be above 50 °f, but cured and maintained at 50 °f. Digital vs chart recorder one of.

Source: precast.org

The general guidelines suggest that the concrete curing temperature must be maintained at >5°c (40°f) for 48 hours (aci 306). If using an enclosure, ensure that the structure is both wind and waterproof. For most testing labs and on site curing processes, a data logger or chart recorder is either convenient or necessary to have: Your auditor may want some.

Source: news.whitecap.com

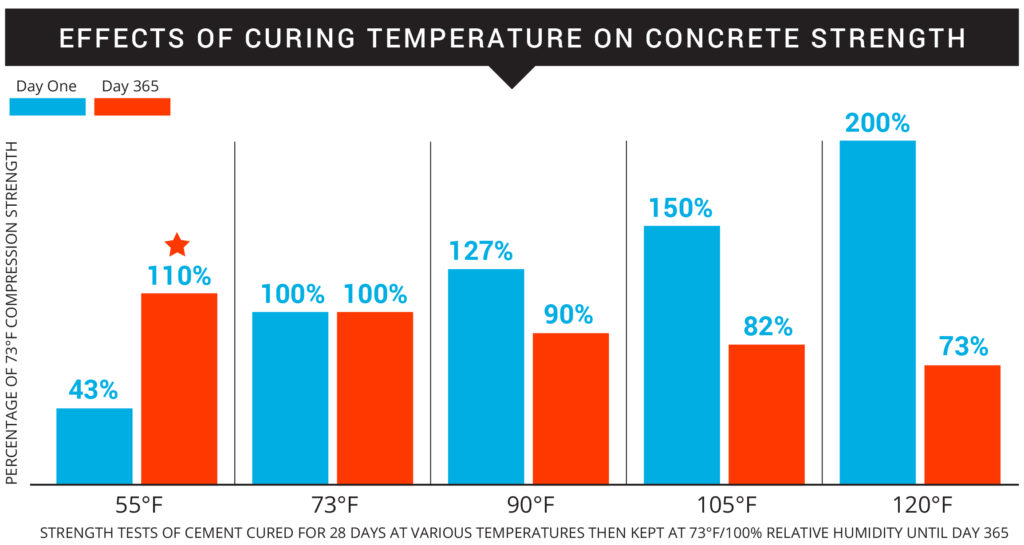

The main components which need to be taken care of are moisture, heat, and time during the curing process. Investigations by paul klieger reported in the portland cement association research bulletin 103 show the strength of type i portland cement concretes at various ages when cured for the first 28 days at temperatures of 120°, 105°, 90°, 73°, 55°, 40°.

Source: www.cement.org

The concrete on this tainter gate trunnion concrete replacement in 2016 required enclosure and heating to keep it at the right temperature during curing. Investigations by paul klieger reported in the portland cement association research bulletin 103 show the strength of type i portland cement concretes at various ages when cured for the first 28 days at temperatures of 120°,.

Source: www.pngitem.com

Concrete is to achieve its potential strength and durability. For applications outside this range of temperatures and conditions, contact sakrete technical service. Concrete strength also depends on the curing of concrete. The addition of what we call 1% should reduce set times of the concrete by approximately 20% to 25% when compared to nonaccelerated concrete at. The curing period may.

Source: precast.org

Curing may also encompass the control of temperature since this affects the rate at which cement hydrates. New concrete can be opened to foot traffic in 24 hours and vehicular traffic in 72 hours. Not maintaining concrete temperature wastes the effects of adding hot water and accelerators. Concrete is kept moist for at least 28 days. For applications outside this.

Source: www.powerblanket.com

The addition of what we call 1% should reduce set times of the concrete by approximately 20% to 25% when compared to nonaccelerated concrete at. Investigations by paul klieger reported in the portland cement association research bulletin 103 show the strength of type i portland cement concretes at various ages when cured for the first 28 days at temperatures of.

Source: www.researchgate.net

Test cylinders for normal strength concrete must be cured according to astm c 31 which specifies an initial curing temperature of 60 to 80 °f cure boxes, blankets or other curing methods must be used in order to comply with astm specifications. If using an enclosure, ensure that the structure is both wind and waterproof. The curing period may depend.

Source: www.researchgate.net

Test cylinders for normal strength concrete must be cured according to astm c 31 which specifies an initial curing temperature of 60 to 80 °f cure boxes, blankets or other curing methods must be used in order to comply with astm specifications. The most frequently overlooked curing aspect is keeping exposed concrete surfaces moist while they are hydrating. When applied.

Source: www.engr.psu.edu

Most of the common people does not know the minimum curing period o. The temperature recorder must be accurate and readable to 1˚c and shall be capable of recording the temperature at least once every 15 minutes. Temperatures approximate setting time 100 ºf (38 ºc) 2 hours 90 ºf (32 ºc ) 3 hours 80 ºf (27 ºc ) 4.

Source: crspgh.com

In a perfect world, the temperature of fresh concrete should be above 50 °f, but cured and maintained at 50 °f. The period can be reduced to 3 days if The temperature elevation range of interest is from ambient to 315°c (600°f). Temperatures approximate setting time 100 ºf (38 ºc) 2 hours 90 ºf (32 ºc ) 3 hours 80.

Source: theconstructor.org

With curing, the period should be as long as practical. How extreme weather affects concrete one of the ways to avoid overheating your concrete in hot weather is to schedule your pours at night when external temperatures are lower. The effect of concrete temperature and retardation of setting time is given by pca in the chart below. Concrete is kept.

Source: www.giatecscientific.com

Concretes, made with two different cements, were cast in the laboratory at temperatures of 10,23 and 32°c (50, 73, and 90”f). Maintaining the proper temperature also plays a vital role in concrete as mentioned, it should not be colder than 5 0 c. For most concrete structures, the curing period at temperatures above 5º c (40º f) should be a.

Source: www.sciencedirect.com

For applications outside this range of temperatures and conditions, contact sakrete technical service. Concrete must maintain a temperature above 50 °f for approximately 48 hours for the correct chemical reactions to take place. Two popular options used during cold weather concrete curing are heated enclosures and insulated blankets. The temperature recorder must be accurate and readable to 1˚c and shall.

Source: www.powerblanket.com

Investigations by paul klieger reported in the portland cement association research bulletin 103 show the strength of type i portland cement concretes at various ages when cured for the first 28 days at temperatures of 120°, 105°, 90°, 73°, 55°, 40° and 25°f, and then cured for the remaining period at 73°f until an age of 365 days. Digital vs.

Source: www.engr.psu.edu

The goal is to make sure the concrete is poured and placed at a temperature of at least 40 degrees fahrenheit and kept there for a period of time appropriate for the type of concrete and its intended use. How extreme weather affects concrete one of the ways to avoid overheating your concrete in hot weather is to schedule your.

Source: www.cement.org

Concrete must maintain a temperature above 50 °f for approximately 48 hours for the correct chemical reactions to take place. There are two options to fulfill this requirement. So, even though we say concrete is cured in 28 days, it will continue to react as long as moisture is present. The curing period may depend on the properties required of.

Source: concretecountertopinstitute.com

So the objective is to keep our young and impressionable concrete damp and at the right temperature (ideally between 50 and 85 f). The general guidelines suggest that the concrete curing temperature must be maintained at >5°c (40°f) for 48 hours (aci 306). With curing, the period should be as long as practical. Your auditor may want some proof the.

Source: inspectapedia.com

The concrete on this tainter gate trunnion concrete replacement in 2016 required enclosure and heating to keep it at the right temperature during curing. The most frequently overlooked curing aspect is keeping exposed concrete surfaces moist while they are hydrating. The goal is to make sure the concrete is poured and placed at a temperature of at least 40 degrees.